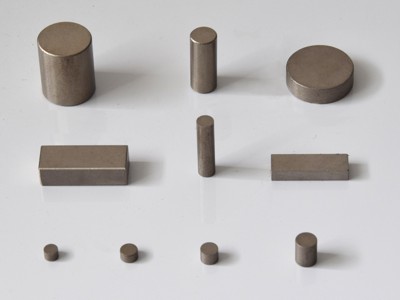

Samarium magnets (SmCo)

Introduction

The chemical base of these magnets is made up of the elements samarium and cobalt in a ratio of SmCo5 or Sm2Co17.

They are manufactured by sintering very finely ground substances as their direct casting is not possible - see Manufacturing technology.

These magnets have high inner energy and hence great portative force with small dimensions (as opposed to traditional ferrite magnets.

Properties

SmCo magnets are hard and relatively brittle, which needs to be borne in mind especially when manipulating magnetised products in the vicinity of other magnets or ferromagnetic materials (iron,...). Magnets are manufactured in standard shapes which can be slightly modified by grinding. However, care needs to be taken so the ground surfaces do not get hot (see the table below - max. application temperature).

SmCo magnets have a slightly lower inner magnetic energy (link to Terms and Definitions in Magnetism) than neodymium magnets (FeNdB), but they have a considerably higher thermal resistance (up to 300oC – see the table below). In addition, they remain virtually intact by corrosion so they do not require a protective surface coating.

While in the past the SmCo magnets were much more expensive than FeNdB magnets, currently the price difference is much lower.

Applications

Permanent SmCo magnets are used in similar applications to FeNdB magnets, i.e. in high-performance electric motors, generators, dynamos, magnetic clutches and brakes and everywhere where high performance and resistance to higher temperatures are required.

Magnetic properties – samarium magnets

| Class | Coercivity | Remanence | Max. product | Max. application temperature |

| HcB [kA/m] | Br [mT] | (BH)max [kJ/m3] | oC | |

| YX-18 | 620-648 | 850-900 | 127-143 | 250 |

| YX-20 | 653-717 | 920-960 | 150-167 | 250 |

| YX-24 | 730-770 | 960-1000 | 175-190 | 250 |

| YXG-24 | 637-732 | 950-1020 | 175-190 | 300 |

| YXG-26 | 748-796 | 1020-1050 | 195-215 | 300 |

| YXG-28 | 756-796 | 1050-1080 | 205-220 | 300 |